H Type Broiler Chicken Cage CE , Full Automatic Broiler Cage Equipment Adela

Product Details:

| Place of Origin: | Hebei,China |

| Brand Name: | BEST |

| Certification: | ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC |

| Model Number: | H type of cage |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | USD 65-200/set |

| Packaging Details: | Normal export packing 20ft / 40HQ container |

| Delivery Time: | 1-3 weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 sets/month |

|

Detail Information |

|||

| Material: | Low Carbon Steel Wire | Use: | Broilers |

|---|---|---|---|

| Type: | H Type | Capacity: | 96-230 Birds |

| Surface Treatment: | Hot Dipped Galvanzied | Accessories: | Frame,mesh,feeding System,drinking System |

| Feature: | Save Space/Time | Usage: | Broiler Chicken |

| Color: | Silver Or White | Name: | Broiler Cage System |

| Size: | 1250mm By 1000mm By 450mm | Application: | Broiler Poultry Field |

| Product Name: | Automatic Chicken Broiler Farm Equipment | Tiers: | 4 Tiers |

| Operation Type: | Automatic | Guarantee: | 10-20 Years |

| Installation: | Supply | Farm Scale: | Medium Farm |

| High Light: | H Type Broiler Chicken Cage,Full Automatic Broiler Chicken Cage,CE Broiler Cage Equipment |

||

Product Description

H Type Full-Automatic Broiler Equipment For Large Broiler Scale Farm In Africa Adela

H type broiler equipment has the advantages of simple structure,low cost,automatic feeding, automatic water,automatic dung cleaning,environment automatic control characteristics.The cage scaffold is made of material with hot dip galvanizing process,and have a lifetime of up to 15 years,usually the broilers quantity more than 15000 consider use it in farm

1. The H type broiler cage

For the broiler cage size usual is 1250mm by 1000mm by 450mm for 4 tiers cage,include the cage frame,mesh,leading end and after end of manure clean system,accessories for installation,base net,support plate,block chicken plate,the brood crib,big crib,lengthways dung cleaning system,head and tail connector of the pressure regulating valve,stay wire of the drinking line,lifter of the drinking line and so on

![]()

2. The automatic feeding system

The feeding system include the silo for stock the feed,the dragon conveying system for transport the feeds from silo to the feeding machine,and the automatic feeding machine

the silo capacity have the 8ton,10ton,14ton....,use the silo hold the feeds,could keep the feeds fresh no contaminate,the silo usually connect with the dragon conveying transport the feeds to the house directly

![]()

Feeding machine

the feeding machine include the support system,hopper traveling system,feed amount adjusting system,power distribution system,turn on the machine when it walks,the feed will be evenly distributed into the feed trough finish the feeding work,use the feeding system could save time,for one 70 meters chicken house finish feeding only need 5-8 minutes,one chicken house only need one worker operate the machine,save more labor

![]()

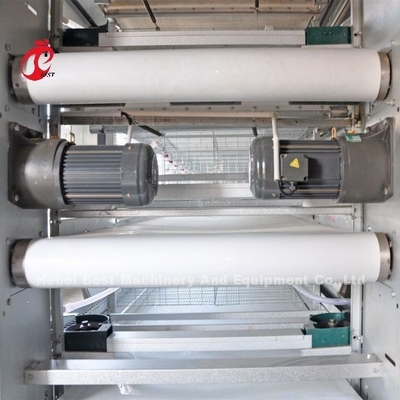

3. Manure clean

For the H type manure clean is the belts way,underneath every tier of cages and towed by driver reducer engines to clean the manure,this strong and robust construction is operated without problem even in very long chicken house

![]()

Rollers and the scrapers located on each tier spills the manure to the discharging manure conveyor at the end of the chicken house and the manure is removed from the house by it

![]()

4. Temperature system

Some farm also will choose the Fan and cooling pad to adjust the temperature in house,make the farm cool

![]()